Cannabis in the Midwest

Pope Scientific is featured in the 'Cannabis in the Midwest' issue of Marijuana Venture magazine. Marijuana Venture’s ongoing feature exploring the cannabis industry’s presence in various regions throughout the [...]

Isolation of CBD

Introduction CBD isolation is performed by many processors to create a THC-free product for their end-user for a variety of reasons. For those who have had the opportunity to [...]

Understanding Short-Path, Fractional and Pope’s Wiped-Film Molecular Stills

Understanding the difference between short-path, fractional and Pope’s wiped-film molecular stills: Oftentimes when people are considering distillation equipment for processing hemp and cannabis, there seems to be a lot [...]

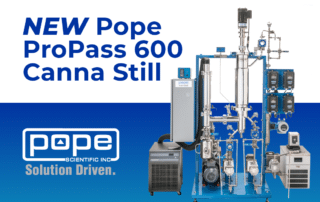

Introducing the New Pope ProPass-600 Canna Still

Providing the highest performance - greatest throughput / price ratio Recognized for decades for molecular distillation excellence, Pope Scientific proudly presents the ProPass 600 series of Canna Stills. This [...]

Pope Exhibiting at MJBizCon 2021

Every year, more cannabis industry deals get done at MJBizCon than any other event by far! Pope is extremely excited to be back in person at MJBizCon. This year [...]

Video: Get to know Pope Scientific

While cannabis is a relatively new market, Pope's processing equipment has been around for over 50 years. Learn more about our equipment, capabilities, customer service and how we support the [...]