Although distillation often gets lumped in with extraction, it’s actually the step after extraction, a process that refines the raw oil, removes impurities, waxes and other undesirable elements, like chlorophyll. It turns the extract from the viscous material often used for dabs into a clearer, flavorless, high-potency oil for use in cartridges, tinctures and edibles.

The process also decarboxylates the material, changing the THCA found in the plant into what is generally referred to as “active” THC, and raising the percentage of THC or CBD to levels above 90%.

“The color and the quality of the oil is better,” says Chris Barone, chief science officer at Clear Cannabis. “Purity, potency, color, odor — all that stuff — is brought up to a higher level.”

An Old Process

Distillation itself is an old process, one used in many industries, but most notably for making alcohol. Traditional short-path distillation, like that of an old moonshine still, uses a boiling flask to heat the material so it evaporates and is caught on a condenser above. The mash is heated in the flask and the alcohol boils off first. It begins to cool when it hits the condenser and then drips into a collection vessel, leaving the water and other substances behind.

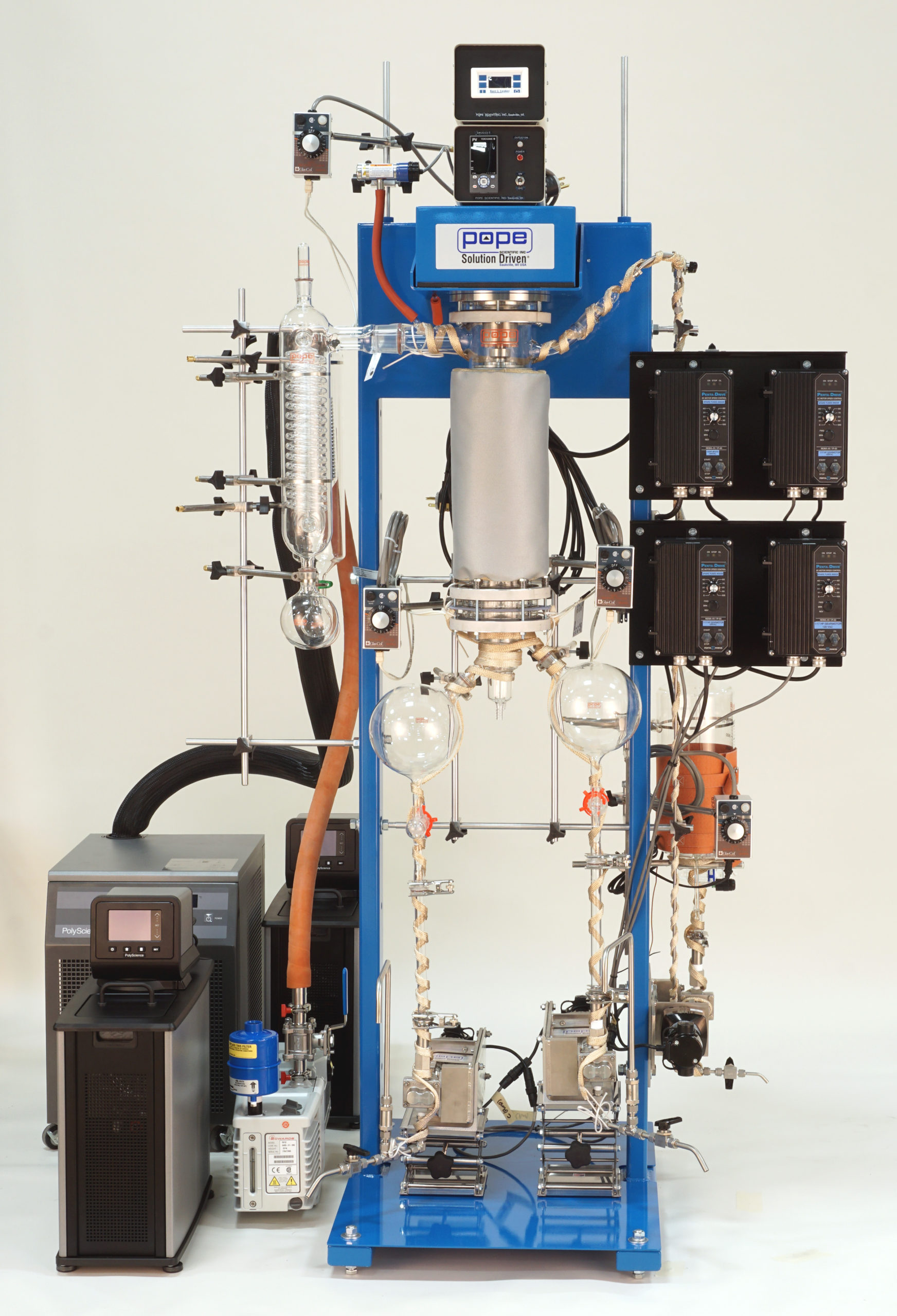

“In that case, you’re driving ethanol off,” explains Dean Segal, vice president of sales and marketing for Pope Scientific.

While this style of distillation was used in the early days of the cannabis industry, boiling the materials for hours at a time degrades the very cannabinoids that the process seeks to distill, resulting in less purity and less yield.

“This problem goes way back to the ’30s and ’40s, when people were starting to distill vitamins and pharmaceuticals,” Segal says.

The solution was lowering the pressure in the chamber.

“Molecular distillation, from a chemistry perspective, is a physical process that relies on heating up the liquid or the resin to its boiling point and separating the constituents of that mixture based on boiling point,” Barone says. “Specifically, molecular distillation is doing it at a substantially reduced pressure.”

The idea is to use a high vacuum to help increase the space between molecules so that they can be boiled and separated at a lower temperature than usual, ensuring a better final product.

“This problem goes way back to the ’30s and ’40s, when people were starting to distill vitamins and pharmaceuticals,” Segal says.

The solution was lowering the pressure in the chamber.

“Molecular distillation, from a chemistry perspective, is a physical process that relies on heating up the liquid or the resin to its boiling point and separating the constituents of that mixture based on boiling point,” Barone says. “Specifically, molecular distillation is doing it at a substantially reduced pressure.”