Decarboxylation of Cannabinoid Extracts

Our application engineering specialists can determine the right equipment for your needs.

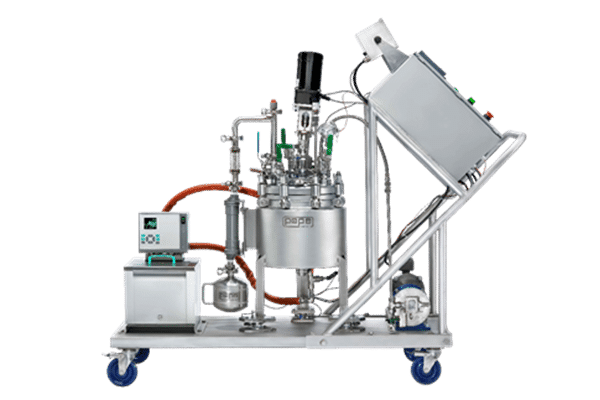

Cannabis decarboxylation is an important processing step in cannabinoid extract and distillate production. It converts the botanical acid form to the neutral, “active” form required for the desired effect when taken by the user. The cannabinoid decarboxylation step can also be used as a finishing step in the removal of volatile materials such as ethanol and any other solvents or water that were not removed prior to molecular distillation. Pope Scientific manufactures ASME code reactor vessels and turnkey systems that can be utilized for this process at all scales and sizes. Adding portability to these vessels/systems is beneficial to allow them to be repurposed as receiver vessels from solvent recovery and feed vessels for distillation systems. View our decarboxylation vessels and decarboxylation reactors below!

A few features that make our systems stand out:

- All wetted parts are made from 316L SS and made in the USA

- Comprehensive QC, manual, and documentation turnover package providing customer’s operations and validation teams with reliable and useful information required.

- Customizable and includes an agitator that is designed for high-viscosity materials

- Available in sizes ranging from 1L to 500L

- One year warranty

- ASME stamped, PED/CE, CRN, and other certifications available.

If you are interested or have a question about our cannabis decarboxylation systems, don’t hesitate to contact us for assistance or request a quick quote.