Reaction & Processing Equipment

Expertly-Designed and Engineered for Application-Specific Requirements

Pope offers a wide range of pressure vessels, from simple storage “cans” to reactors, to complex cannabis processing equipment, and for other specialty applications and industries.

Expertly Designed and Engineered for Application-Specific Requirements Including:

- Decarboxylation, winterization & filtering, evaporation units

- Turnkey custom processing systems, including synthetic cannabinoid reaction, adsorption, concentration, liquid handling centers other applications

- Solvent recycling and purification systems, can incorporate Pope Cannabis Distillation’s Fractional Column Stills

- Storage, shipping, mixing, dispensing, feeding and receiving vessels

- Instrumentation, controls, PLCs and data recording/storage packages available, UL/CSA/CE certification

- Explosion proof, Division 1 and 2 Compliance available

- 316L-SS, Hastelloy and other metal alloys

- Pharmaceutical-grade polishes

- All vessels ASME certified and stamped for vacuum and pressure

- Canadian CRN and European CE/PED certification also available

Contact Pope Cannabis to learn more about our cannabis processing systems listed below. For a quote on a cannabis processing system for your specific requirements, get started here.

Set of 4 Portable Pharmaceutical-Grade Mixing Vessels

Set of 4 portable pharmaceutical-grade mixing vessels, 400-L, 60-L, 6-L, 0.7-L. 316L SS, highly polished interiors, actuated diaphragm bottom drain valves, largest two with Division 1 motors and controllers.

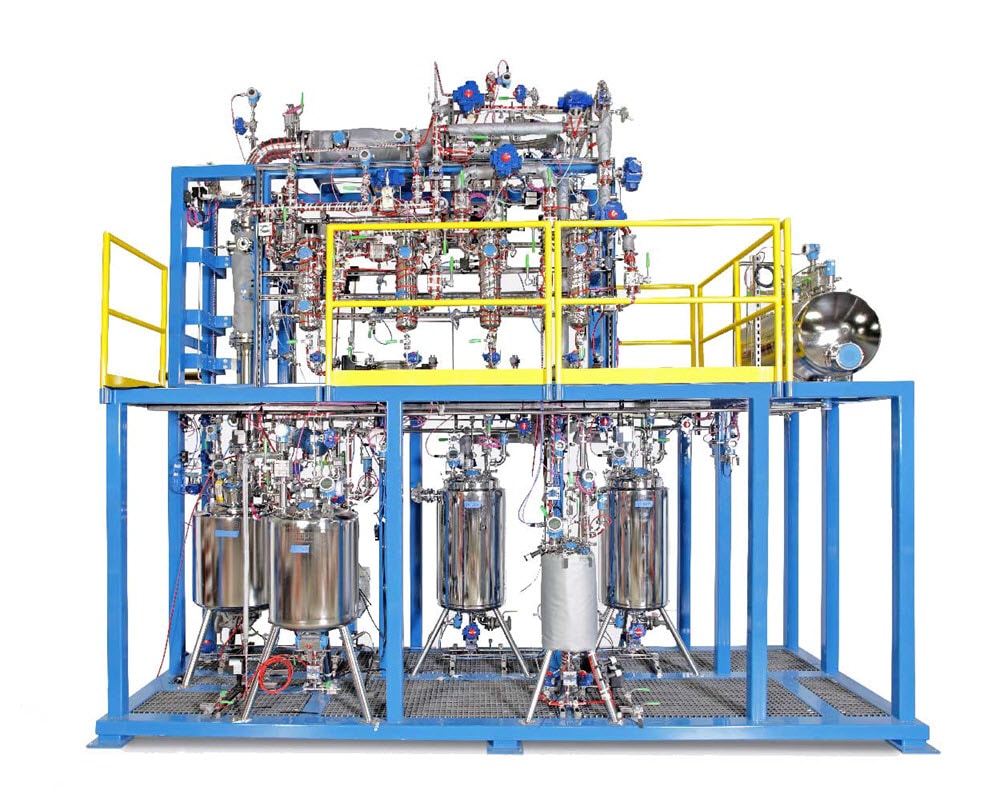

Turnkey Double Reactor Processing System

Turnkey double reactor processing system for advanced battery material pilot development. Computer controlled, with programmable batching, precision flow multiple ingredient feed control, temperature and pressure control, pH control, mechanized vessel head lifts and portable locking addition vessels.

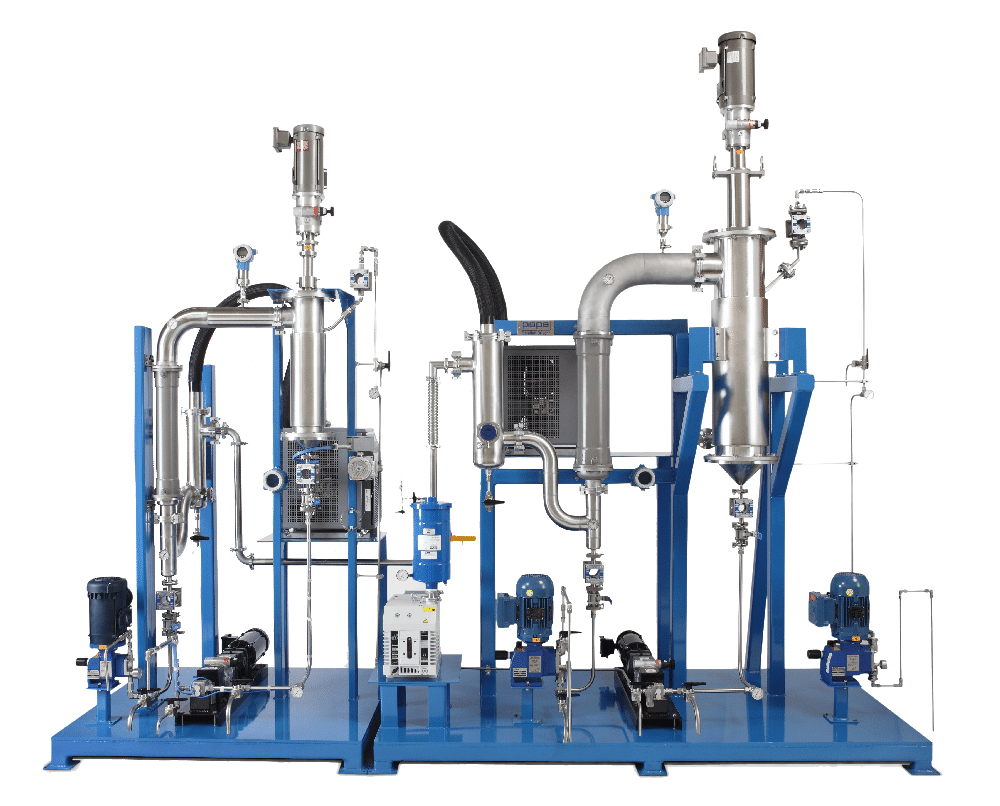

Turnkey Pilot Plant System

Turnkey, continuous mode, fractional column distillation pilot plant system, Division 1, explosion proof, all 316-L SS material, with pulseless reflux ratio dividing, dual control system for either vacuum or pressure operation, coriolis flow metering for all streams and product receivers.

Transfer | Storage Vessel

Order of 38 pharmaceutical-grade transfer/storage vessels, Hastelloy C-22, electropolished finish

200-Liter Fractional Column Distillation System

200-L fractional column distillation system for high melting point hazardous electronics material purification. Division 2 electrical classification. Complex manifold design with 4 cold traps, product, feed and CIP vessels and actuated valving for multiple flow paths.

150-Gallon Reaction | Absorption | Evaporation System

150-gallon reaction-absorption-evaporation system for synthetic cannabinoid production. 316-L Stainless Steel and Hastelloy C-276 construction. With Division 2 electrical rated control and data logging and recording, pneumatic valve actuation and vessel mixing, load cells and portable product receivers.

Pope Cannabis Distillation Turnkey Explosion-Proof 2-Stage 9″ + 6″

Pope Cannabis Distillation Turnkey, Explosion-Proof, 2-Stage, 9″ + 6″, Stainless Steel, Wiped Film Evaporator System for Solvent Removal.