Pope Turnkey Solutions

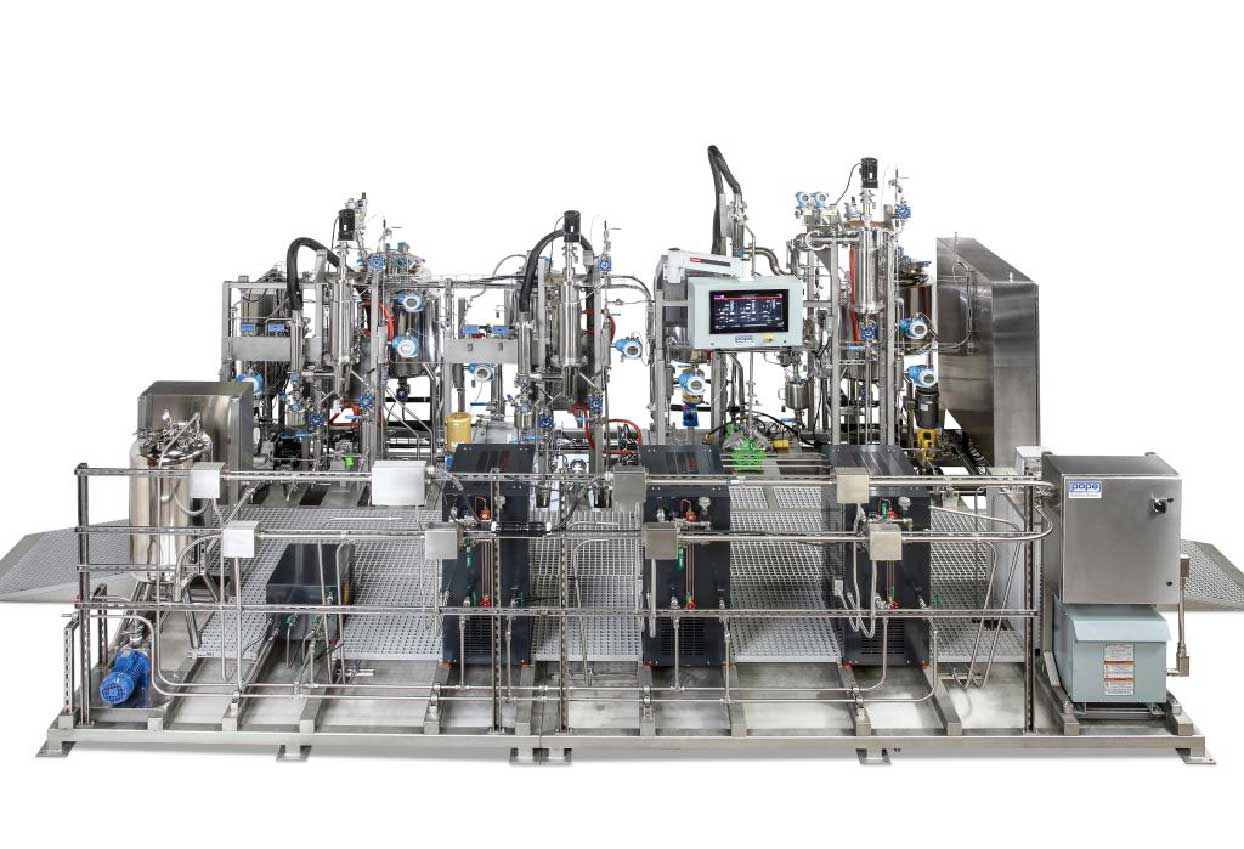

In addition to our standardized Wiped Film Distillation Equipment (2”, 4” and 6” systems) Pope also produces turnkey skid-mounted industrial production systems. Our multistage, stainless steel, PLC-controlled, fully turnkey skid-mounted systems serve major cannabis production installations requiring capacities anywhere from 10 kg/hr up to 100 kg/hr. We are capable of engineering and manufacturing industrial production-sized stills as massive as you need.

The 6″ molecular still system is capable of processing 10 liters/hour of CBD feed material for example. The 9″ + 6″ WFE (Wiped Film Evaporation) system shown can remove ethanol and other solvents from post-extraction or post winterization feed material at up to 50 liters/hr, application dependent.

Along with the increased size and continuous operation comes the same consistency of product composition over time and sustained quality.

10 kg/hr PLC operated 2-Stage Turnkey System.

Turnkey 2-Stage 6″ Stainless Steel Molecular Still System with Computer Control.

Turnkey Explosion-Proof 2-Stage 9″ + 6″ Stainless Steel Wiped Film Evaporator System for Solvent Removal.

All New ProPass Canna Still

This single-stage wiped-film distillation system contains the core essentials for reliable, round-the-clock operation. All 316L stainless steel construction with no glass except for armored sight glasses provides durability and high heat transfer rates for maximum efficiency and throughput.

This design includes new high-performance gear pumps, an oversized vacuum pump, a compact, heavy-duty frame, and more. The result is an industrial machine ready to take on a wide quality range of extracts and provide high purity and yield distillate product.

Large Scale and Industrial Distillation Equipment

Many large industrial installations feature Pope’s post-extraction cannabis distillation equipment.

CBD distillation operations are typically much larger scale than THC purification operations; thus requiring larger scale turnkey equipment.

No matter what size your operation currently is, Pope can supply the right-sized Wiped Film Short-Path Distillation equipment to achieve unmatched post-extraction THC and CBD purity and yield as well as help you scale-up when you’re ready. Pope’s team of experts is also available to help you determine what scale and equipment will work best for your desired product yield and scale.

Turnkey 3-stage PLC controlled,

pharma-grade cannabinoid distillation system.