Wiped Film Molecular Distillation

The Pope Difference in Cannabinoid Purification and Terpene Distillation

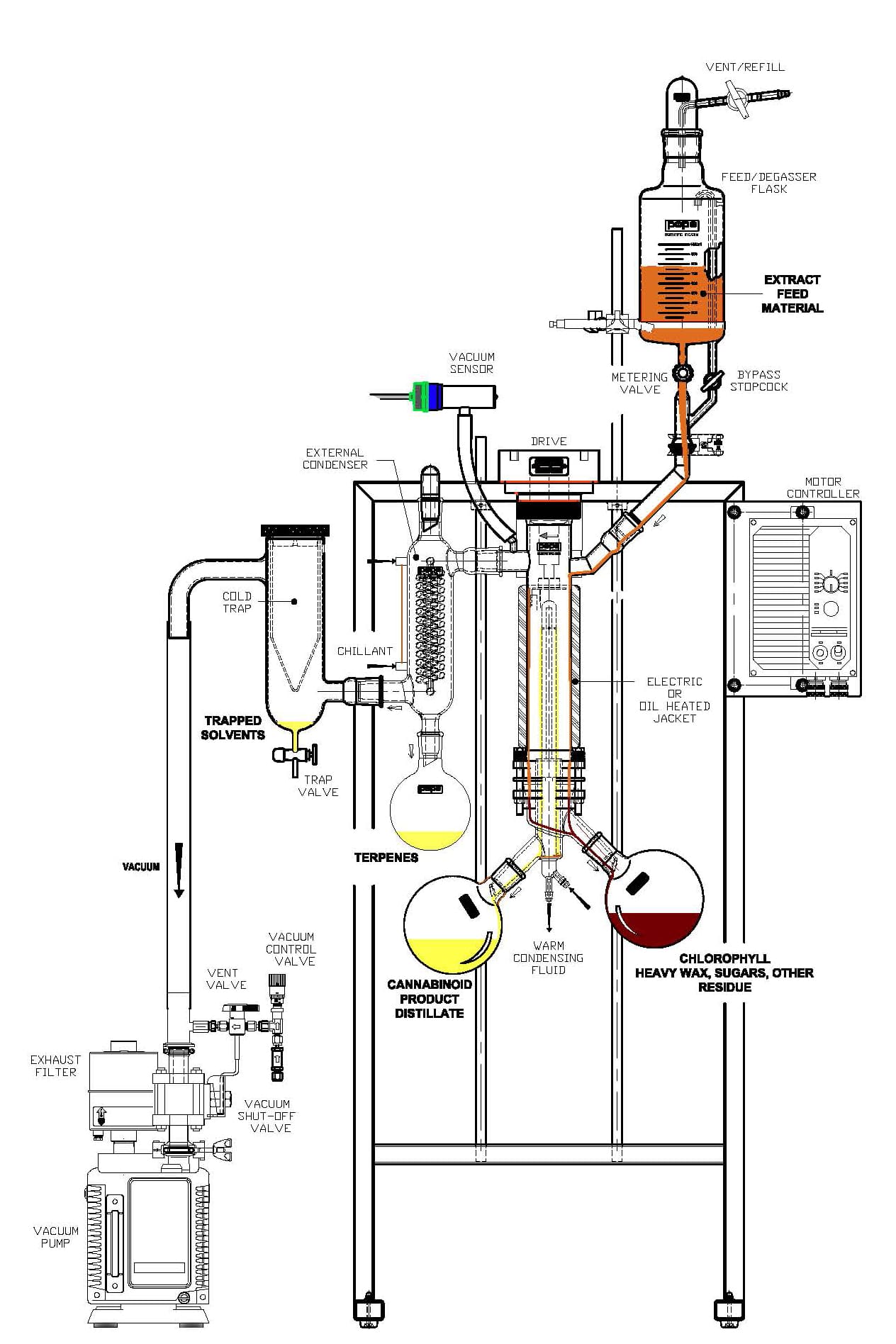

Pope Wiped-Film Molecular Stills are a special type of short-path distillation equipment. These are continuous mode systems, as opposed to simple batch mode boiling flask stills (the latter often referred to as “short-paths”, though ironically, these are not truly short path designs as discussed in the next paragraph). The diagram below of the cannabinoid distillation purification process illustrates the means of this technology and shows the flow of the feed material and the separation of component fractions within the equipment. This same purification process and equipment can be used for various cannabinoid distillation such as the processing of CBD, THC, THCV, CBG, CBT, CBN, CBC & others.

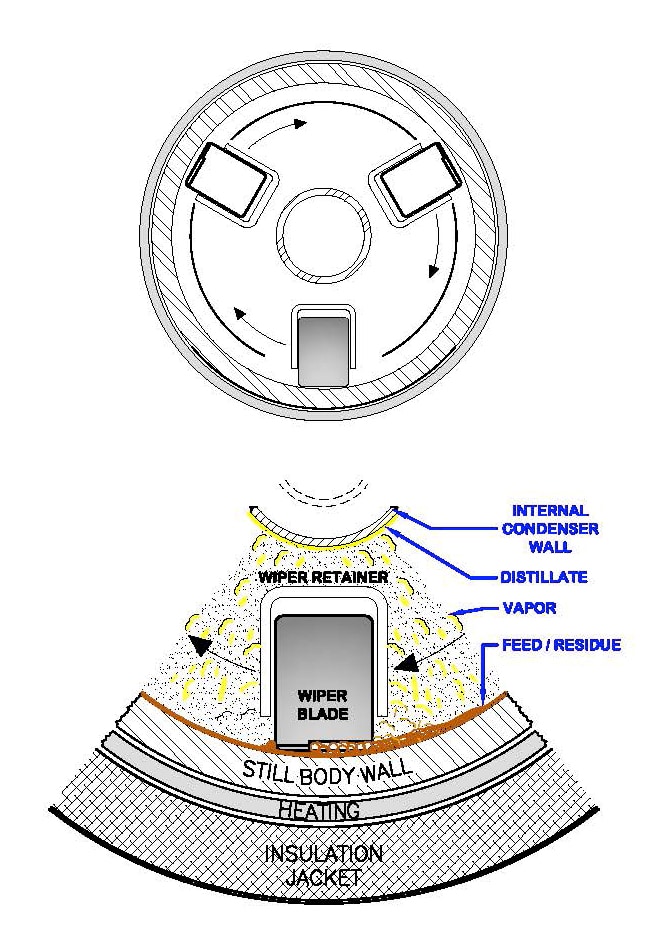

In wiped film processes, feed material is delivered from a feed flask or a pump into the inner wall of a vertical cylindrical evaporation section, heated from the outer wall, (either electric resistance or circulating hot fluid jacket type). Internally, rotating diagonally slotted wipers force liquid around and downward in as highly turbulent, thin film on the inner wall. The moving liquid is heated via conduction through the wall. During the quick journey downward, lighter (lower boiling point) fractions of the liquid begin to vaporize. Heavier residue material (Chlorophyll, large lipids, salts, sugars, heavy wax fractions), does not evaporate and continues the travel down the full length of the still body, falling into a residue receiver flask or discharge pump.

Cannabinoid Purification

Within the evaporation body there is a vertical internal condenser positioned central, parallel, and close to, the full length of the cylindrical evaporation surface, providing a short path for evaporated vapor molecules traveling from the heated surface to the condenser surface. For cannabinoid distillation, the internal condenser fluid must be kept elevated (~70°C) to prevent high viscosity or freeze-up of the condensed THC, CBD, and other component vapors.

Due to the optimized, continuous Pope equipment design, this all happens with high evaporation efficiency and within a number of seconds, (instead of hours of high-temperature exposure in batch type “short-paths”), and under vacuum-lowered temperatures, thus minimizing any possibility of product degradation.

Prior to the cannabinoid distillation pass through the wiped film still, there is a first pass in which terpenes and any other lighter end components are removed by distillation from the feed material and collected as a distillate. The terpenes and other light components can be condensed in the internal condenser and an optional external condenser. The residue from this pass is collected in a different flask or vessel until all the feed material has been depleted. The residue contains the cannabinoids and heavy compounds and this fraction will then be fed through the still again as a second pass as has been previously described. This first pass boosts the cannabinoid percentage and decreases the volatility of the feed material such that the cannabinoid distillation pass will behave better, resulting in optimized purity and yield.

While cannabinoids are caught and collected by the internal condenser, a different, external condenser, maintained at a chilled temperature, can capture terpenes (which are lighter than cannabinoids). The terpene isolate is then collected in another, separate receiver flask. Depending on the composition of the feed material and the goals of the operator some quantities of terpene isolation are obtainable which can be very useful for various product formulations. Any remaining vapors which escape both the internal and external condensers and which may contain small amounts of solvents, water, or lighter terpene components, are collected in a cold trap maintained at an ultra-low temperature. The trap serves the purpose of maintaining lowered vacuum levels in the still system and protecting the vacuum pump from contamination from the light vapors.

It is important to maintain a steady feed rate, body temperature, and vacuum level. In the standard glass molecular still systems, feed rate and vacuum are maintained manually. Pope also offers positive displacement feed pumps, automatic flow rate controllers, automatic vacuum controllers, and other advanced features including product discharge pumps, multiple in-series staged still unit skid mounted systems, and computer/PLC control. As clients’ product production requirements increase, Pope can assist with technology consistent throughout the product line, allowing straightforward process equipment scale-up. Equipment for processing 24/7 at more than 200 kg/hr is offered, well more than sufficient for any cannabinoid application!

The Molecular Background:

Wiped-Film still technology takes advantage of the fact that each chemical substance has a characteristic vapor pressure. It is this relative difference in vapor pressures that dictates how easily a complex compound can be separated into its constituent components.

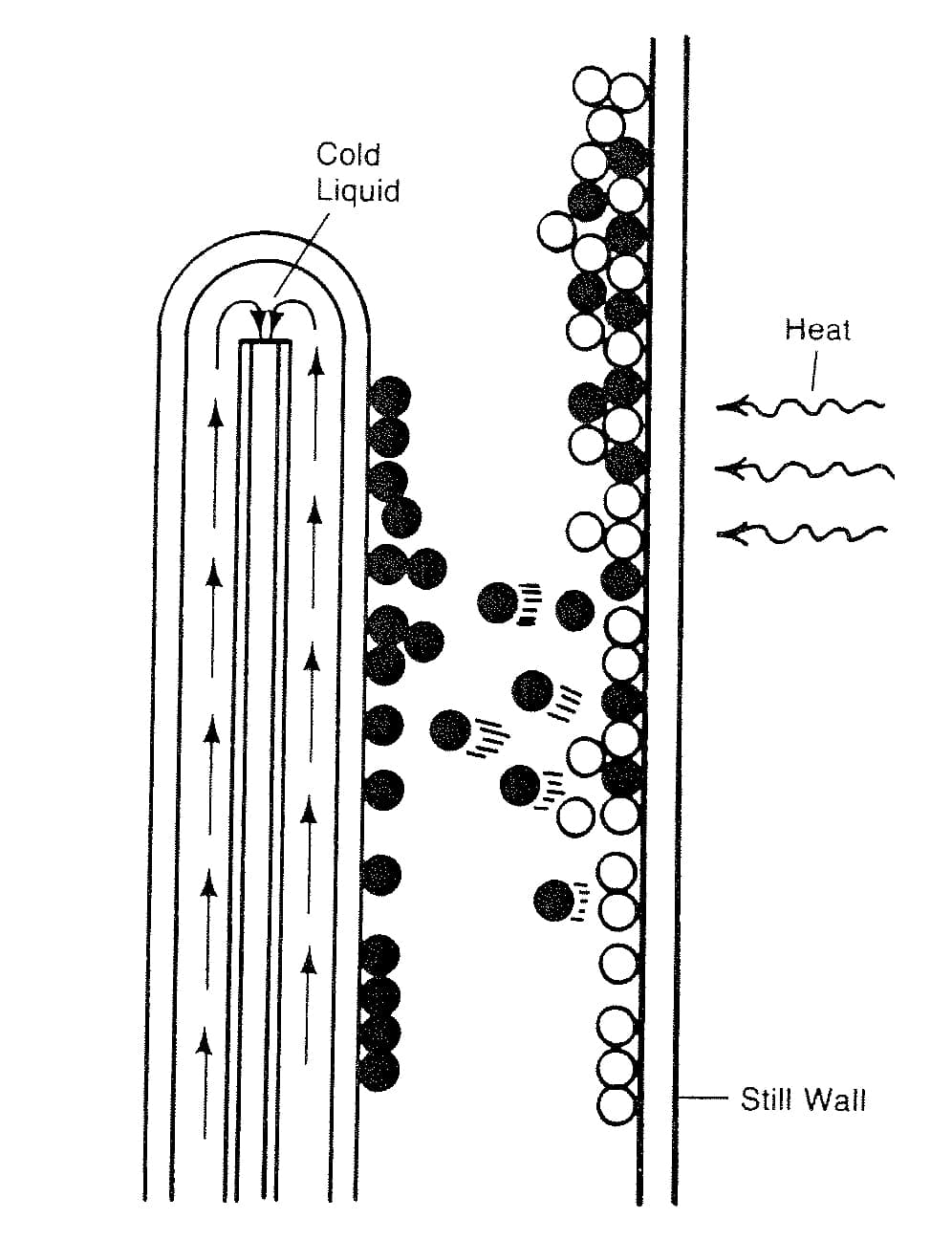

Since the molecules of all matter are in constant motion in varying degrees, depending upon the chemical composition of that matter and the temperature and pressure applied to it, molecules near the surface tend to escape into the surrounding atmosphere. As temperature increases and pressure decreases, this escaping tendency usually increases, and the substance is said to vaporize.

The force generated by these escaping molecules is referred to as the vapor pressure of that material at a particular temperature and pressure. It is the relative difference in vapor pressure of substances that dictates how easily a complex compound can be separated into its constituent compounds.

How the Wiped-Film Still Works:

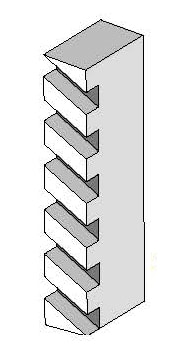

The Pope Wiped-Film Still consists of a heated body into which a fluid system requiring some degree of separation is continuously fed. The fluid is spread into a thin film by a rotating wiper blade assembly driven at a predetermined speed. The film, while being forced into turbulent flow by the wiper blades, progresses down the inside body wall aided by gravity and the slots in the wiper blades.

Have any further questions on short-path distillation? Contact us for further information!

Basic evaporation and condensation

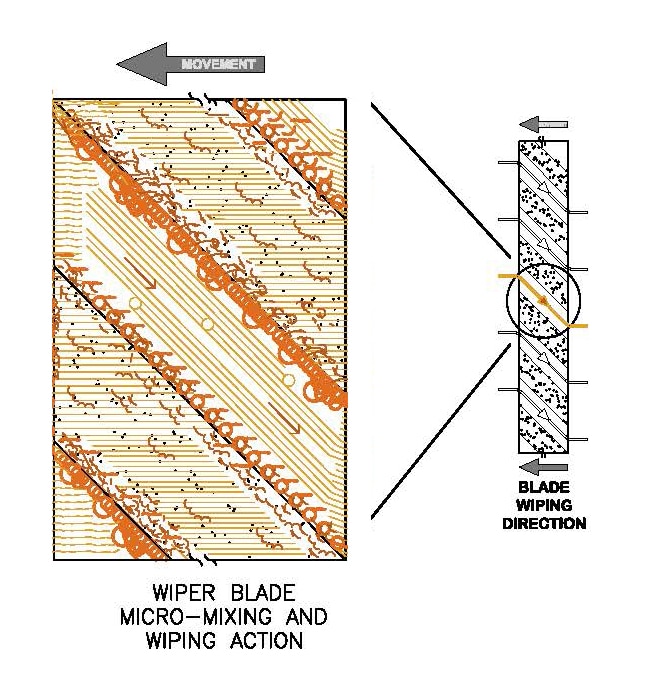

Wiper blade moves each plug of material around and downward.

Thin films are created in Pope Wiped-Film Stills for a variety of reasons:

- Turbulence and micromixing created by a rapidly moving diagonally slotted blade greatly assist in heat transmission, thereby lowering the temperature required on the inside evaporator wall for a given system pressure.

- A maximum resulting surface area per unit volume of flow is generated, facilitating rapid, efficient evaporation.

- The liquid exposure time to the elevated wall temperature can be controlled and completed within a matter of seconds. This minimizes product degradation of heat-sensitive materials by controlling the wiper assembly speed.

- Pope diagonally slotted wiper blades promote plug flow with little back mixing and direct motion both circumferentially and downward. This minimizes dwell time distribution, ensuring that material flowing through the system has a uniform exposure to process conditions.