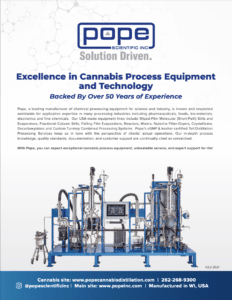

POPE SCIENTIFIC INC.

Industry Leading Hemp & Cannabis Processing Equipment

Backed by over 60 years of laboratory and industry processing experience in molecular distillation, fractional distillation, reactors, crystallizers, vessels, nutsche filter dryers, and turnkey processing systems, Pope Scientific’s Wiped-Film Short Path Molecular Stills have become established as the premier machines in the marijuana industry for cannabis distillation, including hemp oil distillation and terpene recovery after extraction. We have led the way worldwide in high-vacuum molecular distillation and wiped-film evaporation equipment, technology, and processing services since 1975. Final purification of THC, CBD, and other cannabinoid distillates to the highest levels of quality, clarity, yield, and product value is readily performed on Pope equipment. Today, Pope sits at the forefront of cannabis processing technology with cannabinoid distillation, post-extraction, and isolation equipment being provided in the USA and internationally.

Recent Blog Posts & News

Check out our blog for technical articles, upcoming events, best practices, industry news and product updates.

Video: Get to know Pope Scientific

While cannabis is a relatively new market, Pope's processing equipment has been around for over 50 years. Learn more about our equipment, capabilities, customer service [...]

Pope: A Deep History of Providing Equipment and Support to the Cannabis Industry

Founded in 1963, over the years Pope has supplied the cannabis industry with expertise and equipment. Today after celebrating over 60 years of business, we [...]

Choosing the Right Scale of Cannabis Distillation Equipment: A Guide by Pope Scientific

In the burgeoning cannabis and CBD industry, the demand for high-quality distillation equipment is paramount for processors aiming to produce pure and potent cannabis distillate. [...]

Pope is Exhibiting at MjBizCon 2023

Pope is thrilled to be exhibiting at this year's MjBizCon in Las Vegas. We will be introducing our new CE-certified Wiped-Film Still, the WFC-600. This [...]

Video: Get to know Pope Scientific

While cannabis is a relatively new market, Pope's processing equipment has been around for over 50 years. Learn more about our equipment, capabilities, customer service [...]

Pope: A Deep History of Providing Equipment and Support to the Cannabis Industry

Founded in 1963, over the years Pope has supplied the cannabis industry with expertise and equipment. Today after celebrating over 60 years of business, we [...]

Choosing the Right Scale of Cannabis Distillation Equipment: A Guide by Pope Scientific

In the burgeoning cannabis and CBD industry, the demand for high-quality distillation equipment is paramount for processors aiming to produce pure and potent cannabis distillate. [...]

Pope is Exhibiting at MjBizCon 2023

Pope is thrilled to be exhibiting at this year's MjBizCon in Las Vegas. We will be introducing our new CE-certified Wiped-Film Still, the WFC-600. This [...]

Pope Photo Contest

We can’t get enough of your Pope pics! Pope is looking for quality photos that highlight our equipment and how [...]

Video: Get to know Pope Scientific

While cannabis is a relatively new market, Pope's processing equipment has been around for over 50 years. Learn more about our equipment, capabilities, customer service [...]

Pope: A Deep History of Providing Equipment and Support to the Cannabis Industry

Founded in 1963, over the years Pope has supplied the cannabis industry with expertise and equipment. Today after celebrating over 60 years of business, we [...]

Choosing the Right Scale of Cannabis Distillation Equipment: A Guide by Pope Scientific

In the burgeoning cannabis and CBD industry, the demand for high-quality distillation equipment is paramount for processors aiming to produce pure and potent cannabis distillate. [...]

Pope is Exhibiting at MjBizCon 2023

Pope is thrilled to be exhibiting at this year's MjBizCon in Las Vegas. We will be introducing our new CE-certified Wiped-Film Still, the WFC-600. This [...]

Pope Photo Contest

We can’t get enough of your Pope pics! Pope is looking for quality photos that highlight our equipment and how [...]

Equipment & Expertise Trusted By:

“The most important thing to me as a Pope customer– beyond the efficacious nature of their machinery – is that they have a staff of engineers and process experts that are quick to help you optimize their machinery. Furthermore, their customer service is exemplary; Pope Scientific is always attentive to the needs of their customers including rapid troubleshooting and expediting the shipments of replacement parts.”

– Mark June-Wells, Ph.D. , Organic Remedies Inc.

Pope Scientific on Instagram

Happy #420!

We're taking a celebratory look at our history with the cann*b*s industry this year!

Take a look at the link in bio for a close up timeline of Pope's history supporting the #canna industry over the years. The future looks bright!

#happy420 #cannabiz #purewithpope #celebrate #history #cannaprocessing #distillation #cannaresearch #hemp

We've been busy installing some big projects the last few weeks (& months)! This super-skid was just installed at our customer's site in #Toronto, #Canada.

This customer first approached us in 2021 for our expertise in integrating reactors with a filter dryer for their innovative manufacturing process. The project involved scaling up commercial production for their client.

In response, Pope designed and delivered a comprehensive solution – a "super-skid" consisting of reactors ranging from 250 to 1,000 liters, integrated with a #Nutsche filter dryer and vacuum pump system. We also introduced a state-of-the-art "Clean-In-Place" skid by @sanimaticinc for efficient equipment cleaning.

With our enhanced capabilities and certifications, we're better positioned to serve our customer's evolving needs. Have a custom project? We're up to the challenge!

👉 To learn more about Pope's capabilities and to discuss your next project visit: https://buff.ly/3j7e0XL

#customprocessing #nutschefilters #reactors #systems #purewithpope #custom #filtering #Nutsche #customprocessing #scaleupwithpope #scaleup

When choosing the size of cannabis distillation gear for your processing setup, consider production volume, growth projections, and budget. Trust Pope Scientific for tailored solutions to boost productivity and ROI.

🔗 Learn more in our latest blog post. 👉 Contact us to enhance your distillation process!

#CannabisExtraction #PopeScientific #CBD #DistillationTech #WipedFilmEvaporator #CannabisConcentrates #EfficiencyBoost #MaximizeYield #InnovativeSolutions #WipedFilmStill #PurewithPope #ScaleUp

🎉✨ Wishing you a Happy New Year 2024 from the Pope Scientific family! 🌐 As we step into another year, may your journey be filled with success, joy, and prosperity. 🚀🔬 Here's to pushing the boundaries of knowledge, embracing new challenges, and achieving great heights together! 🌟🥳 #HappyNewYear #ScientificSuccess #PurewithPope #PopeScientific #2024

In the spirit of the holidays, we would like to inform you that the Pope office will be closed from December 25, 2023, to January 1, 2024, to allow our team to spend quality time with their loved ones. Our office will reopen on January 2, 2024.

During this period, our customer support may experience delays in response times, and we appreciate your understanding in advance. Rest assured, we will do our best to address any urgent matters promptly.

We want to take this opportunity to wish you and your loved ones a joyous holiday season filled with warmth, laughter, and cherished moments. May the coming year bring you success, happiness, and continued prosperity.

Thank you for being a part of the Pope family. We look forward to serving you with renewed energy and dedication in the coming year.

Wishing you a wonderful holiday season and a Happy New Year!

#POPE #HappyHolidays #MerryChristmas #PopeScientific #HappyNewYear

Our latest install complete! This 6” stainless ProPass 600 is up in running at Cresco Labs in #pennslyvania. Thank you to Pope’s Ryan for performing another successful install.

#popescientific #distillation #wipedfilm #propass #cannabiz #distillationequipment #distill #purewithpope #crescolabs #cresco

A common question we get is "What is the feed rate of your wiped-film stills?" Swipe to see the feed rate of our cannabis still line-up, from our 2" to multistage systems.

Want more info? Check out the link in bio to our helpful wiped-film still comparison sheet.

#popescientific #wipedfilm #feedrate #distillation #popelineup #distillationprocess #distillationequipment #innovation #labequipment #distill #cannabiz #lab #pilotplant #industrial

Come say hi 👋 and see our latest still, the WFC 600 wiped-film distillation system. Booth 6741!

#distillation #wipedfilm #pope #mjbizcon #wfs #cecertified #purewothpope #mibizcon2023

Here we go!! Day 1 at #mjbizcon is here. Come see us and talk about your #cannabis processing needs at booth #6741

#mjbizcon2023 #cannabisprocessing #distillation #wipedfilm

🌿✨ Exciting News! ✨🌿 Introducing Pope's All-New CE-Certified Wiped-Film Distillation System for Cannabis – the WFC-600! 🚀 Join us at this year's #MjBizCon for an exclusive look! BOOTH #6741.

What makes it special? The WFC-600 is a portable, single-point power connection, self-contained modular 6" system designed for high-performance cannabinoid distillation. 🌐 Plus, it's not just for cannabis – versatile for various applications!

✅ CE Certified: Our entire system is CE-certified, covering the whole package, not just individual components. 🌍 This means compliance for use in Europe and other countries with this specification.

Ready to Roll: The base system is complete and ready for cannabis distillate manufacturing. Optional packages are available to cater to your specific preferences and requirements.

For Our Global Community: Pope's WFC series also offers a newly designed, extra-high-integrity, convenient portable cart system for customers in the Americas and other regions not requiring the CE marking.

Get ready for innovation, performance, and reliability – the Pope way! 🚀🌿 Contact us to learn more.

#PopeScientific #WFC600 #CannabisTech #MjBizCon2023 #PurewithPope #cannabiz #distilate #wipedfilm #CECertified #Distillation

Happy Thanksgiving! Wishing you and yours a great holiday and we will see you in #Vegas next week for MjBizCon! We are very thankful for you!

Please note Pope will be closed this week on Thursday and Friday for the holiday.

#happythanksgiving #popescientific #mjbizcon2023 #thankful

We've always prided ourselves on our service and quality equipment. When we get messages like these, it cements our purpose and our appreciation of our customers. Thank you! 🥹

“I have been utilizing Pope’s wiped film stills for over 10yrs and I have found their stills to be extremely reliable, robust, and predictable. The distillates we have produced from their systems are consistently within the range of 90 to 99% total cannabinoids and we are able to easily separate volatile compounds during a single pass through their wiped film distillation systems.

...

The most important thing to me as a Pope customer– beyond the efficacious nature of their machinery – is that they have a staff of engineers and process experts who are quick to help you optimize their machinery. Furthermore, their customer service is exemplary; Pope Scientific is always attentive to the needs of their customers including rapid troubleshooting and expediting the shipments of replacement parts.”

-Mark June-Wells, Ph.D., Organic Remedies Inc.

Learn how we can support you. Reach out!

#customerservice #purewithpope #wipedfilm #distillation #cannabiz #distillate #support

🌟 It's that time of year again... Pope is thrilled to announce our presence at the 12th annual #MjBizCon in Vegas this month! 🎉 Visit us at Booth #6741 to explore cutting-edge solutions for your processing needs.

🚀 We're showcasing our latest innovation, the Pope WFC600 - a fully CE-certified Wiped-film still that's set to redefine standards in the industry. 🔬✨

Let's connect and dive into the future of processing together. See you at #MjBizCon! 👥🌐 @mjbizdaily

Get all the details here: https://buff.ly/46ced1X

#Innovation #CannabisProcessing #CErating #CE #wipedfilm #CEcertified #distillation #distillate #popescientific #MjBizCon2023 #Pope #cannabiz #hemp #cannabinoids #mjbiz #vegas

Happy Halloween from Pope! 🎃 Don't let complex separations spook you... 👻 We're here to help you solve your processing applications with our equipment and exceptional technical expertise. Reach out today.

#happyhalloween #popescientific #processingexperts #chemists #halloween #purewithpope

✨Putting the finishing touches on this 2 stage ProPass 600 wiped-film distillation setup before it heads to its new home. ✨

#propass #popescientific #gmp #botanicals #science #processing #propass600 #lab #wipedfilm #moleculardistillation

Optimize Your Cannabinoid Production with Pope’s Distillation Processing Services 🌿🔬

Considering adding distillation to your cannabinoid production or refining your #distillation process? Look no further! Pope offers a wealth of expertise in wiped-film molecular distillation, with decades of experience.

Our toll distillation services cater to a wide range of industries, from #cannabinoids to pharmaceuticals. We run pilot plant development equipment and lab-scale feasibility testing to help you optimize your processes.

We've been at the forefront of cannabinoid trials and piloting, pushing the boundaries of purity, yield, color, and clarity through distillation. Our 2" lab wiped-film unit and Gas Chromatography (GC) analysis ensure top-notch results.

Whether you're a startup or an established company, we're your trusted partner. Outsource your distillation needs to Pope, licensed by the FDA in food #GMP, kosher, and halal certified.

https://buff.ly/3tNDsu1

Ready to elevate your products? Reach out to us today for testing and tolling solutions! 🚀 #DistillationExcellence #CannabinoidProduction #Innovation #purewithpope #tollprocessing #tolling #wipedfilmdistillation #wipedfilm

Such a great day hosting the @asgs_midwest @americanscientificglassblowers fall meeting in our glass shop! Thanks yo everyone who came out! And thank you to pope’s Chris and Robin for their excellent demonstrations!

#popescientific #purewithpope #americanscientificglassblowerssociety #ASGS #glassblowers #glassblowing #glass #scientificglass #glass #wisconsin #midwest

Always fun to demo the 2” wiped-film at a show. Today and tomorrow we’re at the silicones expo in Detroit!

#wipedfilm #distillation #siliconesexpoUSA #popescientific #purewithpope #polymers #tradeshow #expo #detroit

🎉🔬 Calling all Pope enthusiasts! 🚀 We're thrilled with your Pope pics and we're hungry for more! 📸 Show off your lab game with Pope and get ready to WIN! 💥

🏆 Our Pope Photo Contest is ON! 🏆

🥇 1st Place: $250 Amazon gift card + Pope merch

🥈 2nd Place: $50 Amazon gift card + Pope merch

🥉 Runner-up (3 winners): Pope shirt + Pope merch

📸 How to Play:

1️⃣ Snap an original photo, reel, or video showcasing Pope equipment in your lab or in action!

2️⃣ Share it on Instagram and your Stories, don't forget to tag #purewithpope and @popescientificinc

3️⃣ Make sure you're following us for a chance to win!

4️⃣ Submit your entry by October 31st! 🗓

🎊 Winners will be announced in the first week of November! 🎉 And guess what? The winning photo will be showcased at MJBizCon in Vegas! 🌟 Details Here: https://buff.ly/45nfcfu

Let's show the world the power of Pope! 💪✨ Time to shine and win those amazing prizes! 🎁 #Pope #Distillation #LabLife #PopeContest 🚀 #PhotoContest #CannaBiz #wipedfilm #MjBizCon2023 #MJBizCon #DistillationEquipment #Labs

Photos:

📸 1 @alaskanhashqueen

📸 2-3 @Vapen & @vapencali

👀Harvesting cake with Pope’s #nutschefilter dryer. 💎 Discover the ins and outs of Nutsche Filter Dryers and how they’re instrumental in producing high-quality cannabinoid isolates. From efficient filtration to precise drying, this equipment is essential in processing #CBD isolate.

http://www.popecannabisdistillation.com/nutsche-filter-dryers-for-producing-cannabinoid-isolate/

#CannabisIsolates #NutscheFilterDryers #CannabisProcessing #PureCannabinoids